PRODUCTS | Basics of ELTAS

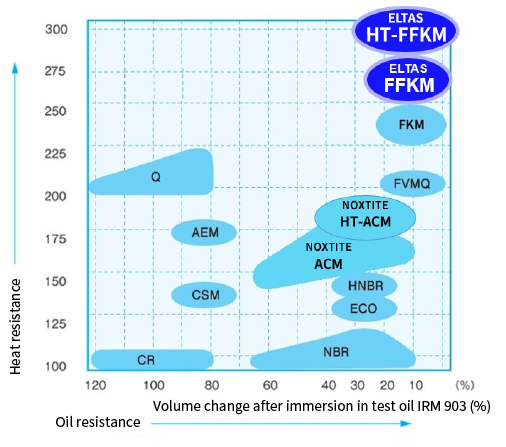

ELTAS is the perfluoroelastomer (FFKM) developed through the rubber synthesis technology and the specialized crosslinking structures cultivated by UNIMATEC over many years.

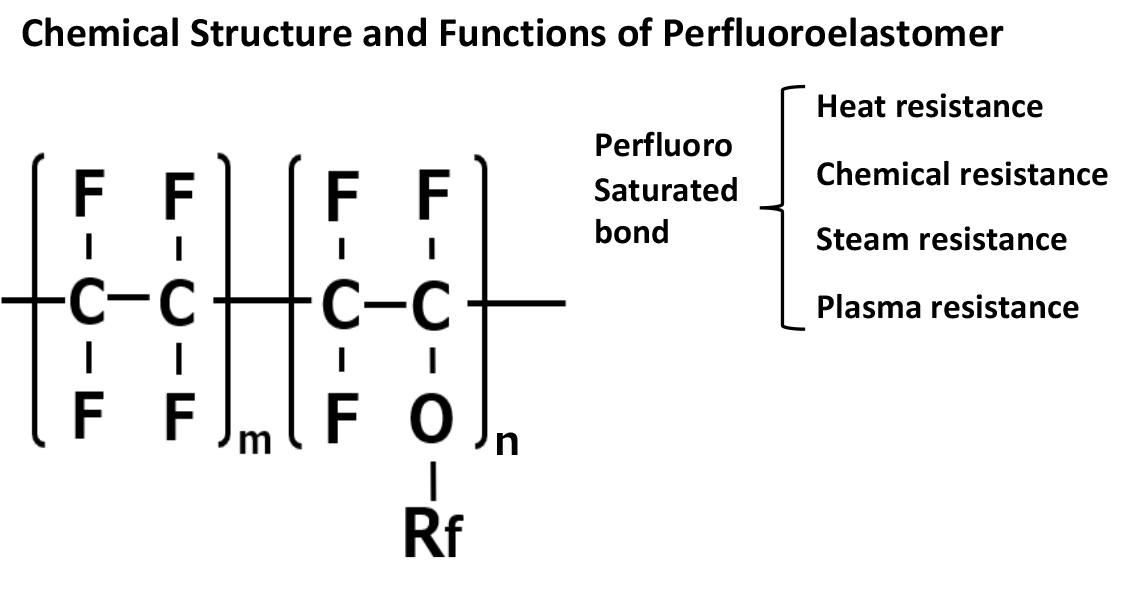

The perfluoroelastomer ELTAS® offers excellent heat, chemical, and steam resistance. Its ability to maintain good sealing properties even in harsh environments makes it a promising choice for various industries and applications.

Characteristics of ELTAS

Key properties

- ・Offers excellent heat resistance, capable of maintaining rubber elasticity even in high temperature environments above 300℃.

- ・Shows high resistance to a wide range of chemicals, including acids, alkalis, amines, and oils, as well as to high-temperature steam.

- ・Less likely to experience weight loss or cracking caused by plasma exposure due to its outstanding plasma resistance.

Characteristics

Due to their unique main chain structure made of strong carbon-fluorine bonds, perfluoroelastomers are chemically stable. They exhibit the highest heat, chemical, steam, and plasma resistance among elastomers. This exceptional performance has led to their growing use as solutions for demanding specifications in sectors like semiconductor industry, aerospace, oil & gas, and chemical plants.

The table below shows examples of our flagship product ELTAS HT-FFKM, high temperature perfluoroelastomers.

| Product Name | Product State | Hardness* | Maximum Service Temperature |

Peak Temperature | Key Features | Recommended Applications |

|---|---|---|---|---|---|---|

| ELTAS HPE800 | Full-compound | 77 | 300°C | 320°C < | Carbon-black blended high hardness type | Heat resistant seals for aerospace, seals for oil drilling equipment |

| ELTAS HPE900 | Full-compound | 65 | 280°C | 320°C < | Non-filler | Seals for semiconductor manufacturing equipment |

| ELTAS HPE905 | Full-compound | 59 | 310°C | 320°C < | Non-filler | Seals for semiconductor manufacturing equipment |

*ISO7619-1

For other FFKM products, please check from the following.

AND INQUIRIES