PRODUCTS | Basics of NOXTITE

NOXTITE is acrylic elastomers (ACM) developed through the chemical synthesis

and rubber polymerization technologies of UNIMATEC.

NOXTITE® with its well-balanced heat and oil resistance, is used in seals, gaskets and hoses in automobiles, contributing to enhance reliability and safety. NOXTITE also has the effect of imparting elasticity and flexibility as an adhesive raw material - NOXTITE is utilized in wide range of industries.

Characteristics of NOXTITE

Key properties

- ・Its wide temperature range from -40 °C up to 185 °C enables your products to maintain long-term reliability over a broad temperature range.

- ・Offers outstanding oil resistance to petroleum-based oils, engine oils, gear oils and torque converter oils even in high-temperature environments.

- ・Suitable for outdoor applications due to its excellent ozone and weather resistance.

Characteristics

Acrylic elastomer NOXTITE offers excellent heat and weather resistance due to its saturated bond in the main chain structure. It also has outstanding oil resistance because of the ester bonds in its side chain structure.

Especially, HT-ACM (high-temperature acrylic elastomer) grade has the properties of less degradation over a long period of time even in high temperature environments.

The table below shows examples of NOXTITE.

UNIMATEC offers a variety of products that meet a wide range of needs, such as heat resistance, cold resistance, among others.

| Type | Product Name | Mooney Viscosity ML1+4(100℃) |

Low-temp Properties TR10 [℃] |

Applications & Characteristics |

|---|---|---|---|---|

| High Temperature resistant (HT-ACM) |

NOXTITE PA-522HF | 30 | -27 | Good for seals and gaskets |

| NOXTITE PA-530 | 26 | -27 | Good for seals and gaskets, good processability |

|

| NOXTITE PA-526 | 36 | -22 | Good for hoses | |

| NOXTITE PA-526L | 27 | -22 | Good for hoses, good processability | |

| Low temperature resistant (LT-ACM) |

NOXTITE PA-44201 | 30 | -39 | Good for ultra low temperature seals |

| NOXTITE PA-44300 | 31 | -38 | Good for ultra low temperature seals, good processability |

|

| NOXTITE PA-42400 | 39 | -28 | Good for low temperature seals |

* For other ACM products, please check from the following.

Evaluation Test

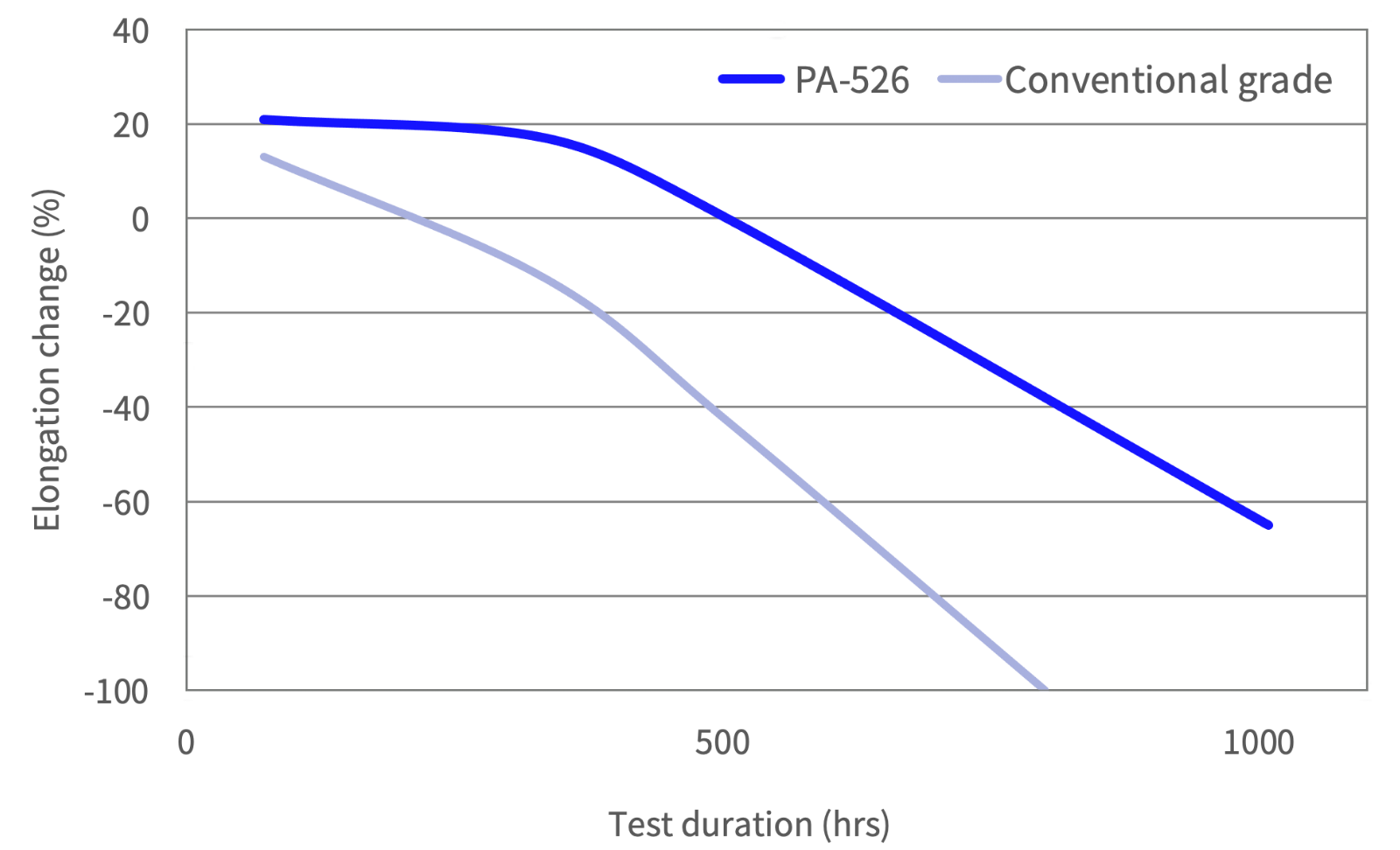

● Heat resistance test results of HT-ACM for hoses (test method: JIS K 6257)

PA-526, a representative grade of HT-ACM for hoses, shows a smaller change in elongation even after being heated at 175℃/1000 hours compared to our conventional grades.

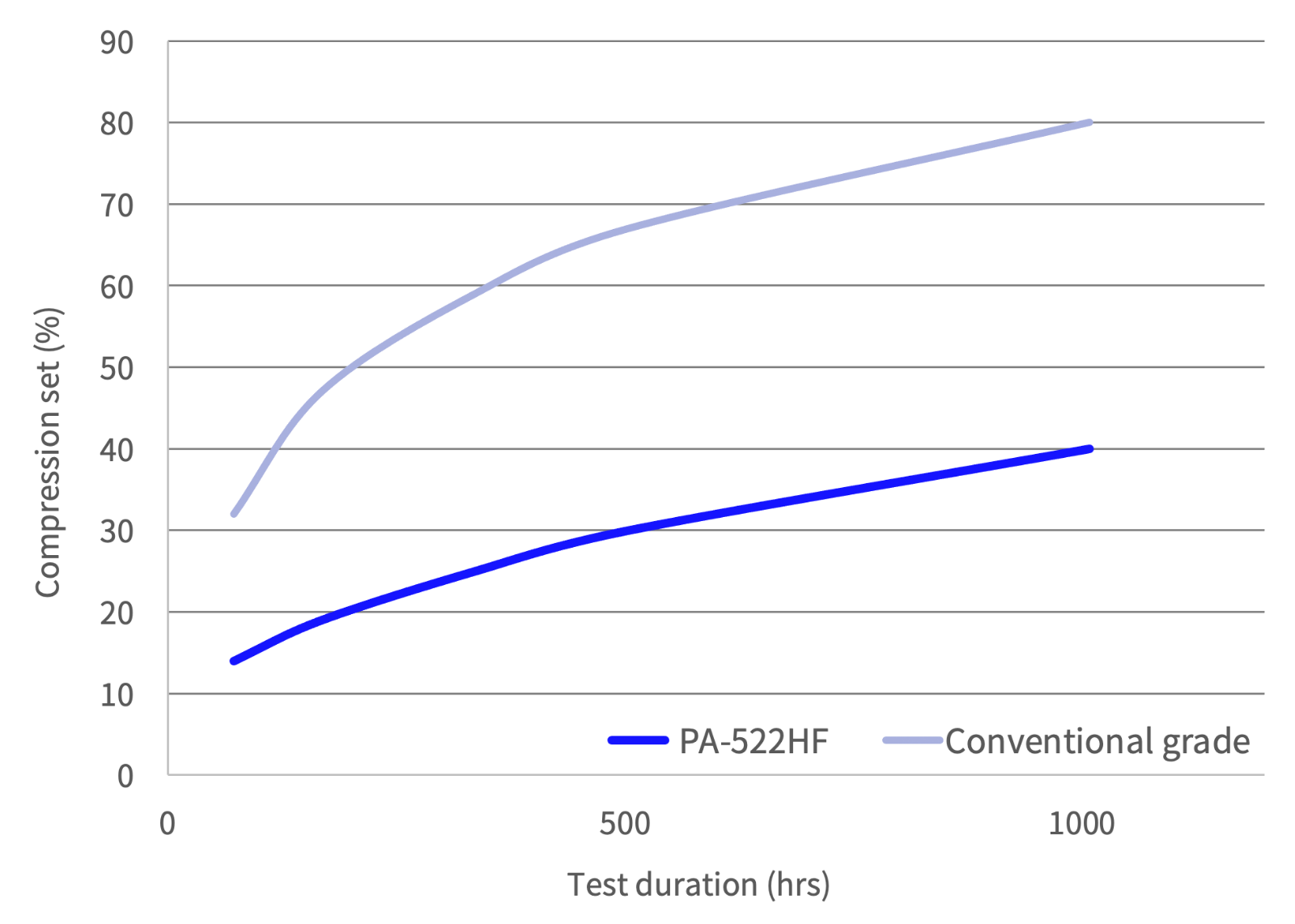

● Compression set test results of HT-ACM for seals and gaskets (JIS K 6262)

PA-522HF, a representative grade of HT-ACM for seals and gaskets, shows good compression set even after being heated at 150℃/1000 hours, and is capable of maintaining sealing properties for a long period of time even in high temperature environments.

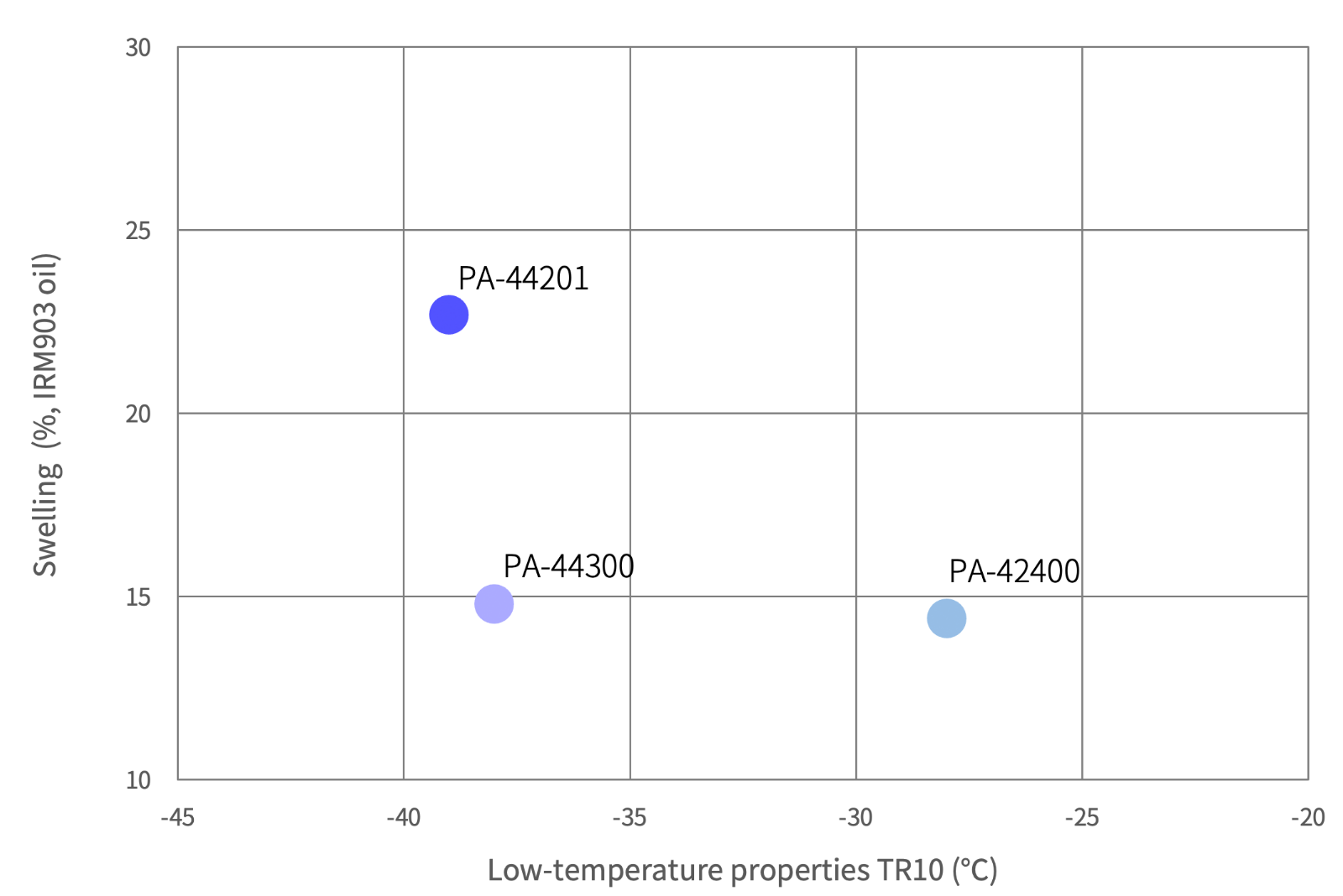

● Cold resistance test results of LT-ACM for seals (TR10: JIS K 6261)

LT-ACM grades for seals, PA-44201, PA-42400, and PA-44300 offer an excellent balance of cold resistance and oil resistance.

* TR: Temperature Retraction test.

A rubber test piece is streched and frozen, and then retraction (= compression set in low temperature) is measured.

Application examples

- ■ Seals (O-rings, oil seals, oil filter packings, head cover gaskets)

- ■ Hoses (Turbocharger hoses, oil cooler hoses)

- ■ Electric vehicle parts (Seals for e-Axle, cooling hoses)

- ■ Others (Adhesives, etc.)

-

Seals -

Gaskets -

Hoses

AND INQUIRIES